Industrial Robot: An Automated Approach

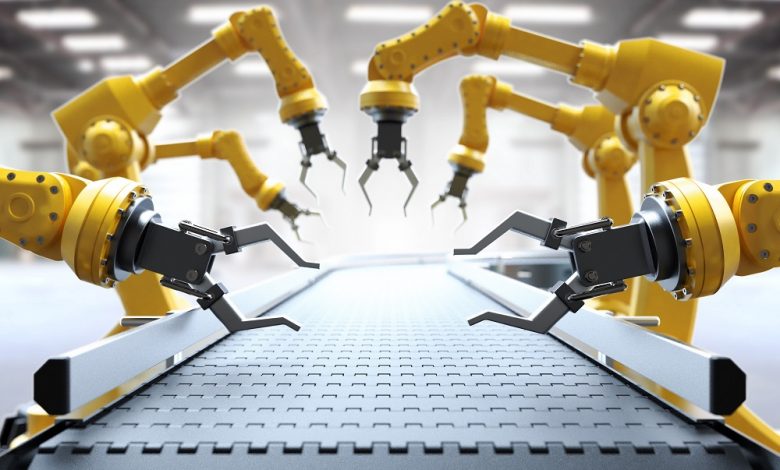

Striding towards a future with an automated approach, manual work has been eased with the replacements by modern technology saving much of man’s time and expenses. Industrial Robot is automated mechanical operations, programmed to move with axes positioned like arms. They come with a majority of 6 axes increasing its capacity to load hefty substances with proficiency.

These Industrial Robots are programmed to operate with software and controls installed allowing authorization over its movements. Saving up on labor, it extends leveraged capacity that even a group of humans would find it impossible to load, further lowering the risk factor. The ability to work through endless shifts and at any hour of the day makes it more appealing. Let’s take a glimpse at some activities that these robots undertake with speed and agility:

· Loading & Handling

Augmenting diverse activities, its primary capacities involve loading and handling materials in the industry. Fastening the process, its dynamic power stimulates the loading of items as large as a car to minor commodities making it highly flexible. Further, its smart programmed build makes it competent in segregating products from one line to another without having to deal with any hassles. It’s picking and placing feature enables this segregation procedure to be in line with the operations of the industry.

· Manufacturing

Distinct Industrial Robots are featured with dissimilar controls enlarging their ability to perform. Some robots are built with the skill to help in the cutting of materials, polishing, refining, sealing robots that help glue things together, spraying robots that make the painting process effortless, welding robots, and finishing robots that add a final touch to your products. With activities spread out widely, finalizing and processing new projects are now manageable with the assistance of mechanical robots.

· Quality Control

Along with rendering activities like transportation, loading, unloading, manufacturing, and warehouse storage convenient with its usage, these robots also make quality control incredibly efficient with its potential to check the quality standard and process products in conformity with the laid standards. Its formulated controls permit it to test the products without missing out on any standards or lowering its quality.

Promoting the power that manual labor can’t quite replace the same way, making industrial operations accurate and fast-paced, it has progressed as a beneficial segment. Being a one-time investment, it saves costs that would otherwise be tied up in the employment of several laborers. If you haven’t endorsed one yet, then your industry is missing out on a major perk.